- Home

-

Products

MID Energy Meter UL Energy Meter Wireless IoT Energy Meter Din Rail Single Phase Energy Meter Din Rail Three Phase Energy Meter Panel Three Phase Energy MeterAMC Series AC Current Meter AMC Series AC Voltage Meter AMC Series AC Power Meter PZ Series AC Current Meter PZ Series AC Voltage MeterAMC16-DETT Base Station Multi-Circuits Energy Meter Acrel ADW300 Wireless Smart Three Phase Power Meter ADW210 Multi Circuits Three Phase Energy Meter DTSD1352-4S Multi Circuits 1-Phase & 3-Phase Power Meter AHKC-EKA Split Core Hall Effect Current SensorAMC16 Series Data Center Monitoring Device AMC100 Series Data Center Monitoring Device Touch Screen Power MeterALP220 Intelligent Low-Voltage Line Protector WHD Series Temperature & Humidity Controller ARTM Series Wireless Temperature Monitor AM Series Medium Voltage Protection Relays ASJ Series Residual Current Relay ARTU Series Remote Terminal Unit

-

Solutions & Application

- Acrel IoT Energy Power Online Management Cloud & Platform System

- Solar PV Enegry Monitoring & Management Solutions

- Prepaid & Postpaid Electricity Management Solutions

- Medical IT System Insulation Monitoring Solution

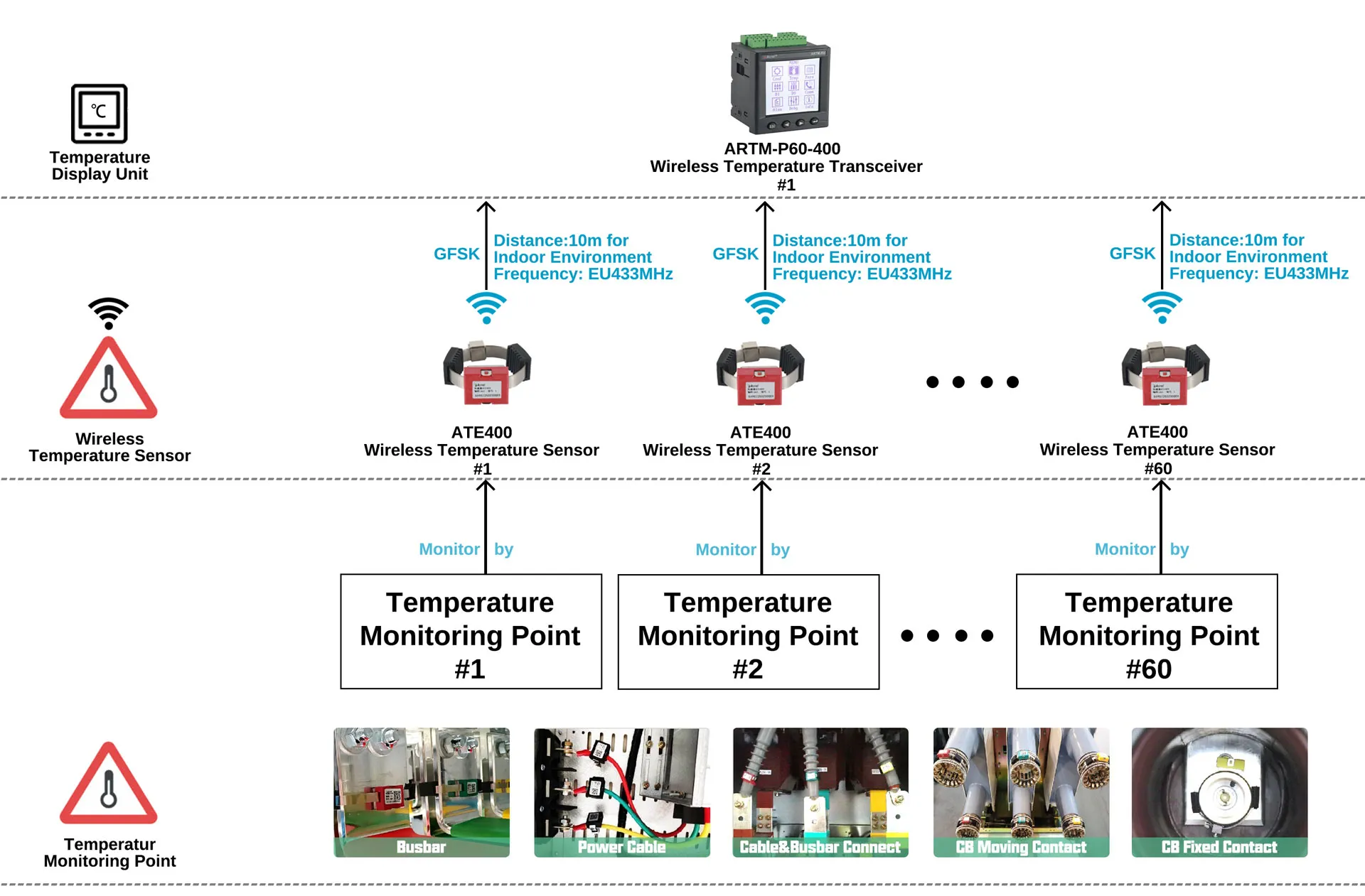

- Wireless Temperature Monitoring Solutions

- Data Center Energy Monitoring & Management Solutions

- Charging Pile Energy Management Solution

- WHD Temperature & Humidity Monitoring & Controlling Solution

- Base Station Energy Consumption Monitoring & Management Solution

- Support Center

- Projects & Blog

- About Us

- Contact Us

EN

EN

fr

fr  es

es  pt

pt  de

de

Call us on:

Call us on:  Email Us:

Email Us:  No. 253, Yulv Road, Jiading Zone, Shanghai, China

No. 253, Yulv Road, Jiading Zone, Shanghai, China